Your safety and satisfaction are our paramount priorities.

Our expertise in insulation solutions can help you optimize your systems for peak performance and sustainability.

Global Green Engineering & Supply Sdn. Bhd. (GGES) is incorporated to provide environmental engineering services to its wide range of clients throughout Sarawak, ranging from giant oil & gas industries, heavy metal industries, and power plant industries to small and medium scale palm oil mill, plywood industries, cement industries, hazardous waste incinerator, chemical industries and etc.

As one of the leading safety, health & environmental engineering firm based in Bintulu, Sarawak, GGES provides a comprehensive professional Engineering & consultancy service across wide range of engineering, safety and environmental issues, with our services being provided under the following main areas:

- Registered CEMS and PEMS Supplier and Tester with DOE Malaysia

- Supplying, Delivery, Installation and Commission of Continuous Emission Monitoring System – Data Acquisition System (CEMS-DAS) & Continuous Emission Monitoring System – Data Interface System (CEMS-DIS)

- Malaysia’s Authorised Distributor for supplying, installation, and commissioning of Continuous Emission Monitoring Systems for ENVEA, FIVES PILLARD OPASTOP, FUJI, DR. FOEDISCH and SINTROL CEMS Analyzer

- Competent in carrying CEMS Performance Audit which include Functional Test, QAL2-CVT, QAL3-OGPM, AST in compliance with version 7.0 CEMS guidelines 2019

- Competent in carrying third party calibration for opacity, Total PM, pressure, pH, weight, temperature measuring instruments

- Provide services for stack emission monitoring (Total PM & Gas)

- Design, Install and Commission performance monitoring equipment, control panel, PLC circuit, electrical distribution board, SCADA, remote monitoring unit, Modbus, wireless communication and etc.

- Performance Monitoring Equipment for Air Pollution Control System

- Monitoring System for Wastewater Treatment

- Supply, install and calibration of water flowmeter

- Provide in house calibration for temperature, pressure measuring devices, balance etc.

Flue Gas Monitoring Equipment

Multi Gas Analyzer (Cold Dry, Hot Wet Extractive)

FUJI ZRE

- Extractive analysis

- NDIR measuring principle

- Measure up to 5 gas components: SO2, CO, NO, CO2, O2

- TUV (QAL1) & MCERTS

- EN15267(3) & EN14181 Certification

DR. FOEDISCH MGA12

- Extractive analysis

- NDIR measuring principle

- Measure up to 6 gas components: SO2, CH4, CO, NO, CO2, O2

- TUV (QAL1)

- EN15267(3) & EN14181 Certification

DR. FOEDISCH MCA 10

- Measure Up To 12 Gas Components Simultaneously

- CO, CO2, NO, NO2, N2O, NH3, SO2, CH4, CH2O, HCI, HF, TOC, H2O & O2

MIR9000e

- Non-Dispersive Infrared Gas Filter Correlation method (NDIR-GFC)

- Measurement of NOx, SO2, CO, O2, residual H2O, CO2, CH4 and N2O (greenhouse gases)

- Automated drift control function

- Smart analyser including AMS control functionalities

- Ultra-low power consumption

Total Particulate Matter (Total Pm) / Opacity Analyzer

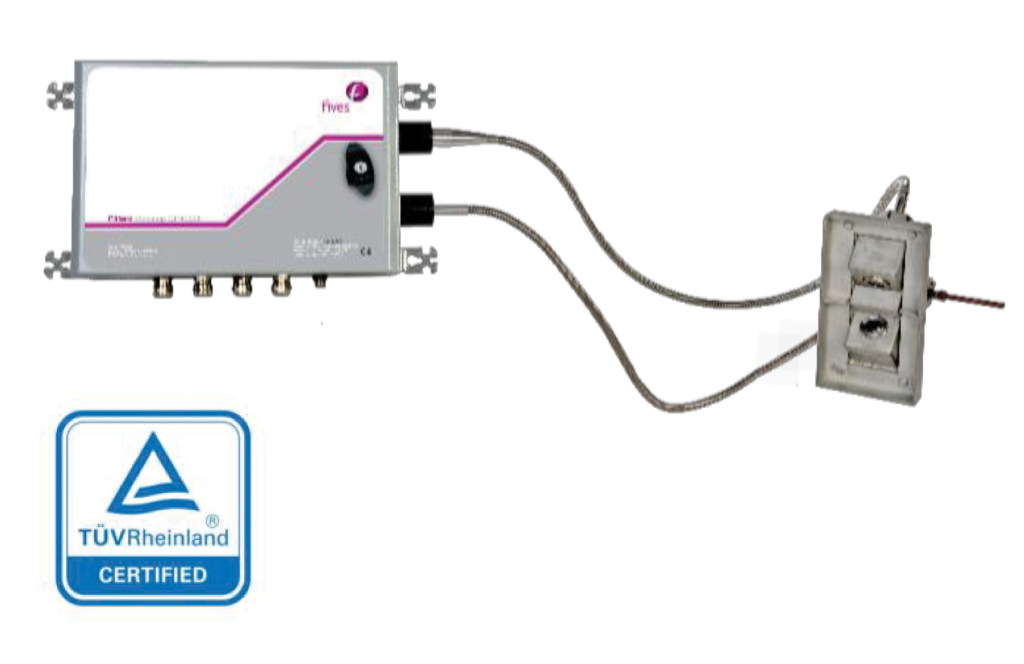

FIVES PILLARD OPASTOP GP4000H

- Automatic monitoring and correction of soiling or contamination of optical boundary surfaces

- Back scattering measuring principle

- Single scanner head for simplified installation

- LED Technology

- Adapted for very low dust concentration levels

- Permanent & full self-diagnosis

- Optical Filter Verification

- Parameters measured: Opacity & Total PM

- TUV (QAL1)

- EN15267 (3) & EN 14181 Certification

CALIBRATION CONTROL UNIT

- Purpose built factory calibration and test facilities to ASTM D 6216 98

- Reduce maintenance down time with simple to service system design

- Used to perform QAL2-CVT and QAL3-OGPM on OPASTOP GP4000H in compliance with DOE’s requirement

DR. FOEDISCH PFM20

- Light & Compact

- Robust Design

- Not affected by vibration

- Easy to maintain

- TUV (QAL1)

- EN15267 (3) & EN14181 Certification

SINTROL S305QAL

- Measuring dust based on inductive electrification principle

- Simple one-sided installation and no alignments required

- Local display with status indication

- Flow velocity compensation 3 – 40 m/s

- Not affected by vibrations and consumable spare parts are not required

- TUV (QAL1) & MCERTS

- EN15267 (3) & EN14181 Certification

PCME QAL 991

- Robust design unaffected by product build-up on the sensor rod

- No additional services such as air purge required, providing lower cost of ownership

- Automatic recording of drift checks (zero and span) to satisfy QAL3 requirements

PCME QAL260

- ProScatter™ Backscatter sensor technology

- Automatic Functionality Check – fully interrogates the optical system

- Purge Flow Fail Sensor option with inbuilt automatic optical shield activation

- Manual and remote Zero and Span (reference) checks available to ensure optimal instrument performance and to comply with EN 13284/QAL1

Sample Sampling and Conditioning System

Heated Sampling Probes & Accessories

Heated Sample Line

Sample Gas Cooler

Performance Monitoring Equipment (Air & Liquid)

Air Flow Meter

- Continuous measurement of exhaust gas velocity, exhaust gas flow, pressure and temperature

- Compact unit with differential pressure probe

- Can be used in flue gases with high dust contents

- Suitability tested and certified according to EN15267 (3) (QAL1) & EN14181 Certification

Differential Pressure Meter

- Electronic differentialn pressure transmitter

- ±1% full scale accuracy

Pressure Sensor

- To measure pressure drop across air pollution control equipment

pH Meter

- Portable hand held or fitted pH meter

- To measure pH value of make-up water and feed water for wet scrubber

Liquid Flow Meter

- Measure flow rate of make-up liquid and feed liquid for wet scrubber

Temperature Transmitter

- To measure flue gas temperature

- Generate signal output

Temperature Gauge

- Measure flue gas temperature

STACKFLOW 200

Continuous high-quality measurement of flue gas velocity, temperature and pressure

Manual reference self-checks for quality assurance and regulatory compliance

MCERTS & TÜV (UBA) certified to EN15267-3

QAL1 certified as defined by EN14181

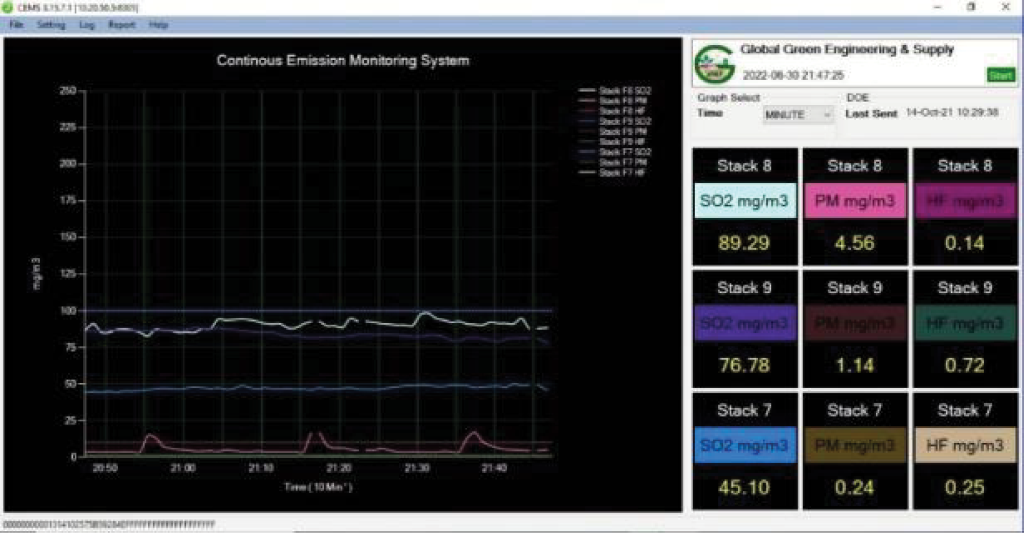

Version 7.0 CEMS Dis Software With Iremote Feature

CEMS User Interface

Communication Linking with DOE iREMOTE System

- Real-time Reporting Software System (for the Client) with minutes, half hours, daily, monthly and yearly report with pdf printing function

- Print-Reporting system for Total PM, Opacity & gas emission data in accordance with DOE’s format for the purpose of submission to DOE on monthly basis

- Additional features that complied to Version 7.0 CEMS guidelines 2019 include:

- Alarm Screen,

- Calibration Report,

- QAL3-OPGM Control Chart and

- JPAHC Form

- Included Data Linking to DOE iREMOTE System

- Custom-tailored design and its application system according to client’s needs

- Display of operation status signal. For example: standby, service, malfunction, calibration etc.

Building lasting partnerships through trust and transparency

We tailor our CEMS solutions to your unique needs, providing personalized support that ensures system reliability, regulatory compliance, and optimized performance.

Calibration On Performance Monitoring Equipment

Perform calibration services on performance monitoring equipment such as air flow meter, differential pressure meter, pressure sensor, pH meter, liquid flowmeter, temperature transmitter and temperature gauge

Stack Emission Monitoring

- Perform stack emission monitoring and sampling for Total PM and Gas parameter

- Laboratory analysis by the accredited laboratory

- Report submission to DOE

Predictive Emissions Monitoring Systems (PEMS) Software Integration and Audit

- PEMS are software-based solutions able to deliver reliable real-time emissions estimations exploiting advanced mathematical or statistical models.

- GGES is a registered tester by DOE to carry out PEMS audit

- Engineer with high skills and knowledge has successfully completed more than 80 audit works nationwide

CEMS Performance Audit (QA/QC)

Our company is a registered CEMS Tester with DOE which can conduct CEMS Performance Audits including Functional Test, QAL2-CVT, QAL3-OGPM, AST and submit report to DOE.

- Quality Assurance Level 2-Calibration Variability Test, QAL2-CVT is the calibration and verification against the appropriate standard reference methods (SRM) by a series of parallel measurement for the quality assurance of the CEMS conducted every three years.

- Quality Assurance Level 3-Ongoing Performance Monitoring, QAL3-OGPM is a series of regular zero and span checks which the results are input to control charts for monitoring the zero and span drifts. While CEMS ensure that air emission pollutants are within set limits and standards, it is the QAL2-CVT and QAL3-OGPM that ensures CEMS are producing accurate yet reliable readings conducted at manufacturer’s maintenance interval.

- Annual Surveillance Test (AST) is an annual check of the CEMS to confirm that the calibration

function is still valid and it still meets the set uncertainty requirements.